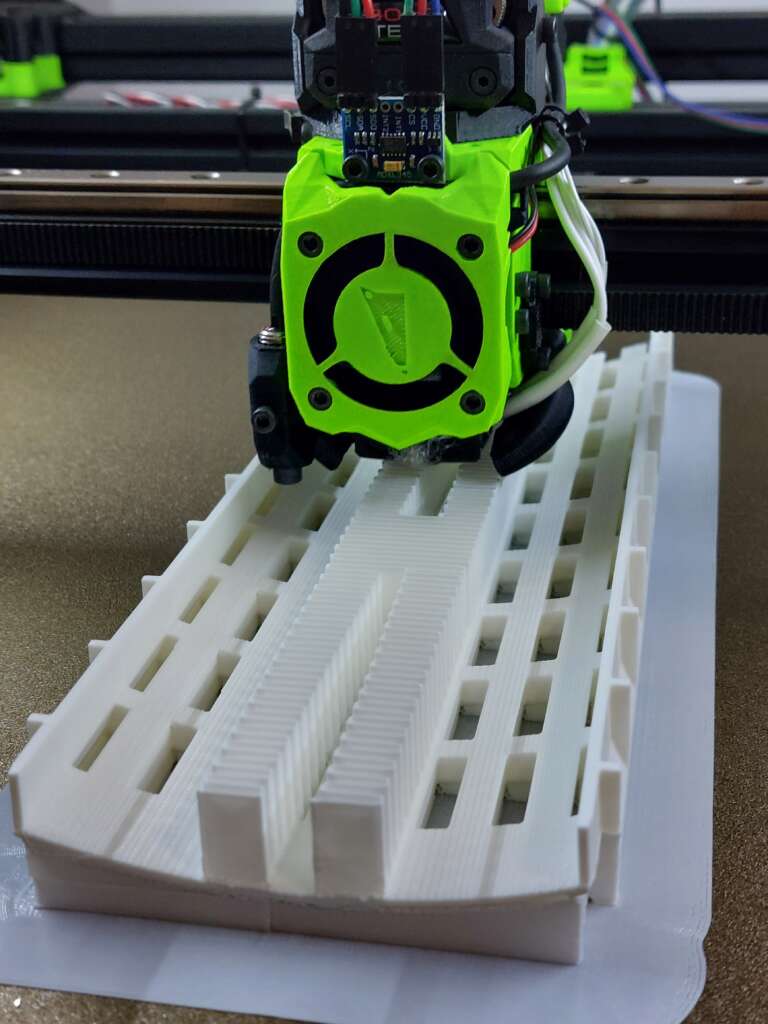

FDM (Fused deposition modelling) printing

FDM (FFF) technology is one of the most widely used and cost-effective additive manufacturing technologies. Concept models, prototypes and end-use parts can be made from real thermoplastics. During production, the filament is fed into the extruder head, where it melts on exposure to heat and is then fed through the nozzle into the work area. The part is built up by the continuous movement of the extruder head. The technology can also be used to produce closed hollow products. This technology also requires the use of a support material, which can be made from the raw material of the product or, in the case of multi-extruder machines, from a separate support material.

Layer thickness: 128, 178, 254, 330 µm

Printing sizes:

- 220x220x250 mm

- Ø230×300 mm

- 500x500x500mm

Materials: PLA, PETG, ABS, TPU, HIPS, PVA, PA, PC, PA-CF, PA-GF, NYLON, PP, ULTEM, PEEK etc.

The materials we use are resistant to temperatures up to 300°C, but also have excellent resistance to abrasion, chemicals, solvents, oil, radiation and other extreme environmental influences.

Click here to request a quote.